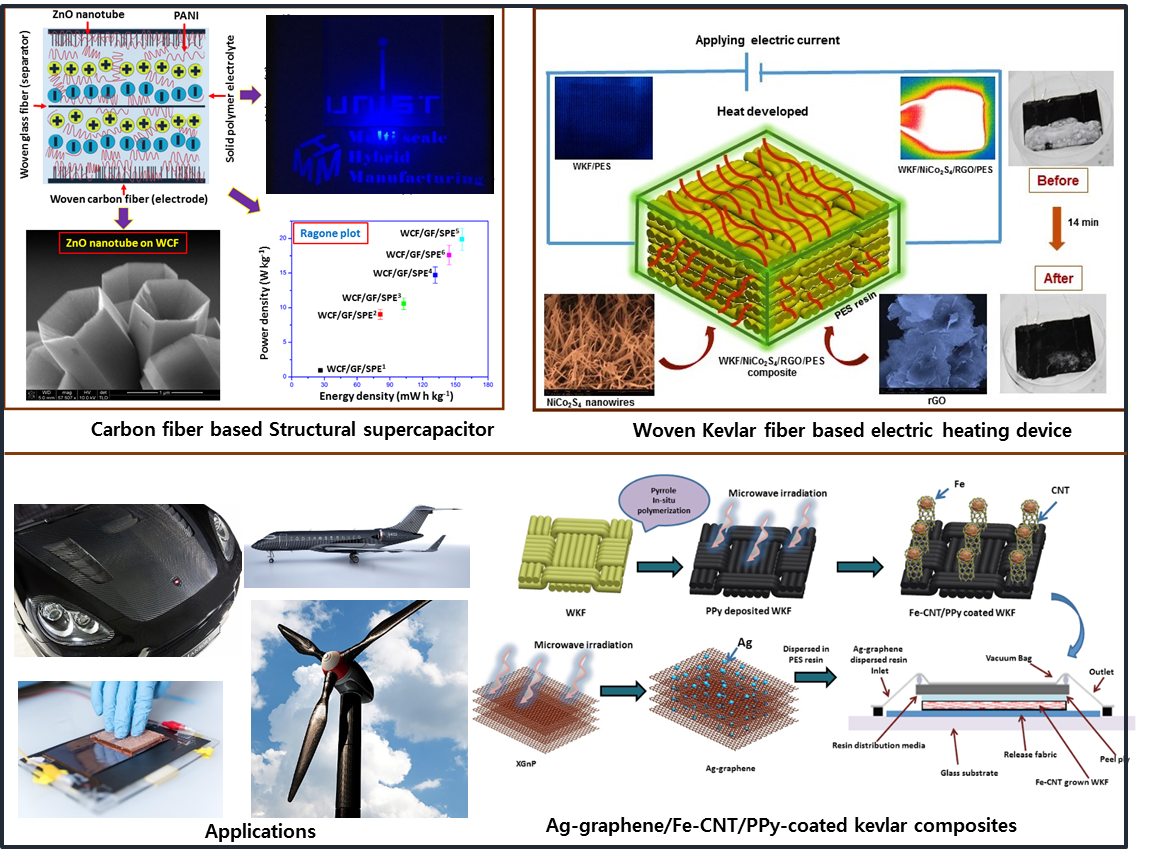

– Woven carbon fiber/Kevlar fiber were surface modified by metal oxide, sulfide, selenide nanowires/nanorods which is followed by composite development in combination with thermoset resin such as polyester, vinylester, epoxy etc. by vacuum assisted resin transfer molding (VARTM) process. This modification technique offers substantial enhancement of mechanical performance and improve impact resistance of the product.

– Develop the technology of surface heating by carbon fiber and Kevlar fiber to handle against the upset situation of aircraft due to structural damage and icing, and safety-critical flight control.

– Multifunctional structural supercapacitor is one of most challenging research in present time. We attempt to develop the technology associated with woven carbon fiber, Kevlar fiber and glass fiber for structural supercapacitor to replace the body of automobiles to a storage device. It will counter the mechanical damages and at the same time supply energy to run the vehicles.

– Electromagnetic Inference (EMI) shielding in aircraft are in strong demand in commercial, civil, and military fields for their potential in electromagnetic wave attenuation and absorption providing effective shielding from such unwanted electromagnetic signals. It also provide protection of the aircraft from lightning strikes. Develop the technology for outstanding dielectric and/or magnetic loss properties with suitable electrical conductivity are essential for an effective EMI shielding material.